Download the 2025 Operational Excellence in Oil & Gas Summit Event Guide

The 17th Annual Operational Excellence in Oil and Gas Summit is returning in 2026 as the premiere meeting point for operations leaders looking for smarter, faster, more sustainable path ways to operational excellence.

Whilst we work behind the scenes, you can explore our 16th Editions Event Guide for a glimpse at everything that took place in November 2025!

In the current oil and gas operating environment, operational excellence isn’t just about boosting efficiency or reducing downtime - it’s about operations where technology, process, and people move as one.

Join over 300 operations leaders and change-makers in November 2026 to explore a smarter, faster, more sustainable path to operational excellence. Learn how leading oil and gas companies such as Marathon, Equinor, Shell, Entergy Texas, CenterPoint Energy, ExxonMobil, bp and more, have delivered high impact wins on critical priorities - while building long-term momentum through team-driven transformation.

Set your 2026 strategy with confidence using new knowledge which will show you how to:

- Identify quick win projects that improve processes and maximise operational efficiency

- Enable workforce and culture transformation to future proof your business

- Identify the digital transformation projects that will drive tangible business value and ROI

November 2025 marked our biggest year yet, featuring a 70+ speaker faculty, 12 pre-conference workshops, 12+ operator-led case studies, 6 interactive discussion groups, a culture focused masterclass, and more!

Sponsorship Prospectus - Operational Excellence in Oil & Gas

Now in its 17th year, the Operational Excellence in Oil & Gas Summit brings together over 350 senior level executives to share use cases and discover trailblazing technologies that will transform their operations.

As a sponsor of the summit, you’ll be at the forefront - driving the conversation, showcasing your solutions, and connecting with decision-makers who are transforming industrial performance.

Our audience is actively seeking solutions to optimize efficiency, minimize risk, and accelerate digital transformation across complex industrial environments. From process automation and predictive maintenance to AI-driven insights and frontline workforce enablement - your solution could be exactly what they need.

Position your brand as a catalyst for change in Houston - download the Operational Excellence Summit Prospectus today.

"It was great working with you onsite. Definitely one of the best teams I’ve worked with." - Marketing Director, ALULA

Operational Excellence in Oil & Gas | Event Agenda

The Operational Excellence in Oil and Gas Summit is returning for its 17th year in 2026.

Whilst we work behind the scenes, you can explore our 16th Editions Event Guide for a glimpse at everything that took place in November 2025!

In the current oil and gas operating environment, operational excellence isn’t just about boosting efficiency or reducing downtime - it’s about operations where technology, process, and people move as one.

Join over 300 operations leaders and change-makers in November 2026 to explore a smarter, faster, more sustainable path to operational excellence. Learn how leading oil and gas companies such as Marathon, Equinor, Shell, Entergy Texas, CenterPoint Energy, ExxonMobil, bp and more, have delivered high impact wins on critical priorities - while building long-term momentum through team-driven transformation.

Spot a session that you'd like to get involved in? Securing your sponsorship package early gives you first pick of the workshops, keynotes and more in 2026, plus 5 months of marketing to senior oil and gas professionals. Get in touch with the team to learn about the full breadth of sponsorship opportunities on offer.

5 Strategies to Win the War for Talent in Oil and Gas - with Insights from Delek US, Shell, Nine Energy Service and Halliburton

Whether it’s quiet quitting, the great resignation, changing workforce demographics or the perceived “dirtiness” of the industry, the oil and gas sector has been struggling to recruit and retain the talent it needs.

The industry has been particularly hard hit by a convergence of long-standing trends: retiring baby boomers, a societal and industry-wide shift towards sustainability, and the digital transformation of work.

In a recent EY survey of young Americans, over 62% responded that they consider a career in oil and gas “unappealing,” and 39% responded that they consider it “very unappealing.” Many young people believe that the oil and gas industry is a dangerous and dirty industry that contributes to climate change.

“A seismic cultural shift is under way that will make it increasingly difficult for oil and gas companies to attract and retain knowledgeable, highly skilled workers — undermining the industry’s ability to succeed in a rapidly changing world,” write the E&Y authors.

Over half of workers in the oil and gas industry have said that they expect to work in a different industry in the next five years, according to a recent survey.

What can oil and gas companies do to attract and retain the talent that they need to thrive in the decades ahead? This ebook, produced in conjunction with our upcoming Operational Excellence in Oil and Gas Summit, looks at key tactics, leadership qualities and ways in which operational excellence can help.

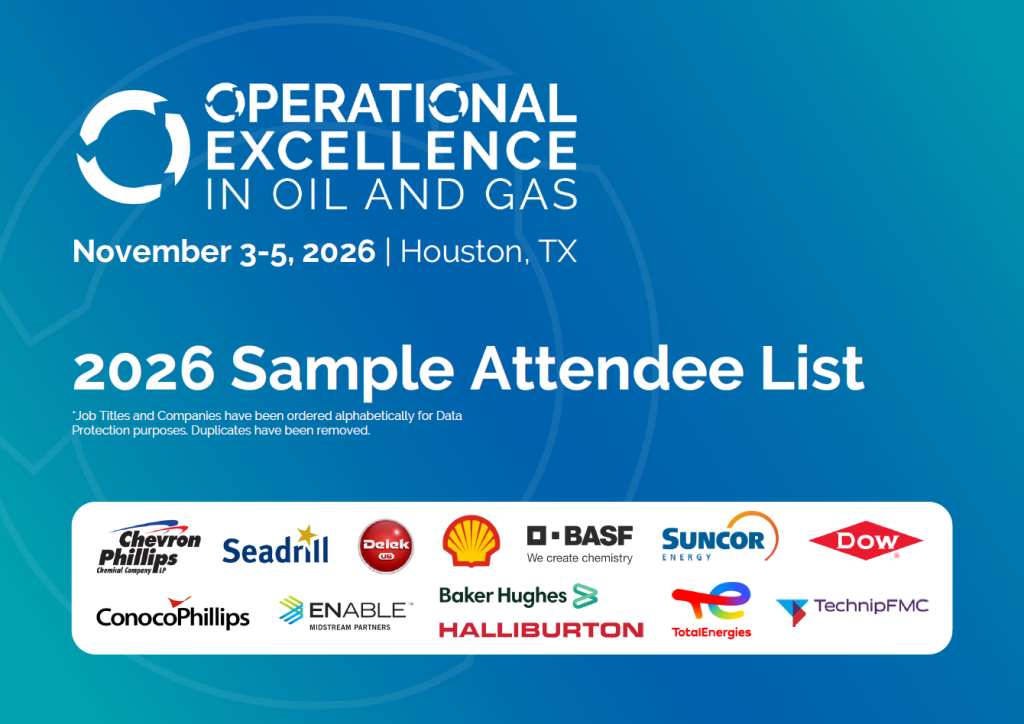

Sample Attendee List - Operational Excellence in Oil & Gas Summit

Wondering who you'll meet at the 17th Annual Operational Excellence in Oil & Gas Summit? Download the Sample Attendee List for a glimpse of who you could be joining on November 3-5 in Houston, Texas.

Bringing together 300+ senior leaders from across the oil and gas value chain, our attendees are decision-makers responsible for driving efficiency, safety, technical innovation and cultural change within their organizations.

They come from leading energy companies, looking for trailblazing solutions in key areas such as:

- Process Optimization

- Intelligent Asset Management

- Digital Transformation

- Human-Centered Operational Excellence

7 Factors for Successful Digital Transformation to Support Operational Excellence in Oil and Gas

How do biggest players in the oil and gas industry support Operational Excellence through Digital Transformation? Get Insights from Chevron Phillips Chemical, Phillips66, Delek US, Dow, EDF Renewables, bp, Buckeye Partners and QuarterNorth Energy today!

Improvements in digital technology have enabled oil and gas companies to dramatically increase efficiency and improve safety in their operations. The industry is increasingly making use of drones, wearable technology, robots, big data, and more. However, while Industry 4.0 promises enormous benefits to oil and gas companies, it can be difficult to implement. Digital transformation is much more than a technology project. It requires organizational, process, behavioral, and even cultural change.

Read our report '7 Factors for Successful Digital Transformation to Support Operational Excellence in Oil and Gas' today!