Beyond Automation: Why Industry 4.0 Hit a Ceiling and Industry 5.0 Holds the Key

How Industry 5.0 Redefines the Future of Manufacturing

Add bookmark

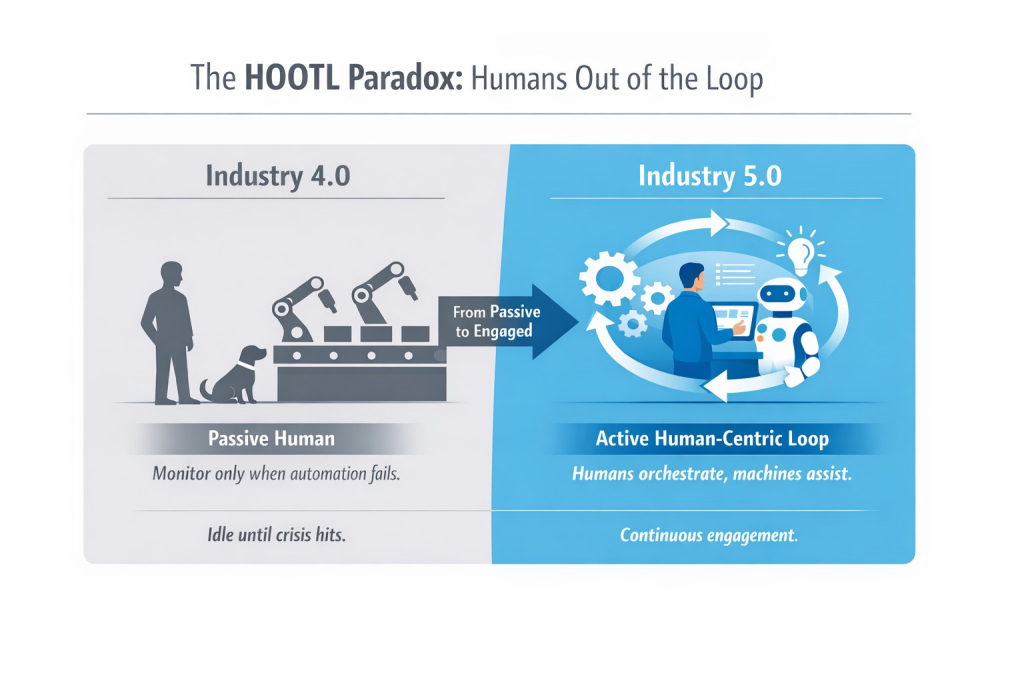

Industry 4.0 promised a revolution. Visions of automation, real-time analytics, heightened operational visibility and ‘lights-out’ factories paint a future of unprecedented efficiency. Some leaders even envisioned a world so autonomous that only a man and a dog would be needed: the man to feed the dog, and the dog to keep the man from touching the machines (Bennis, 1997). See Figure 1.0.

Figure 1.0

Figure 1.0

Yet for many organizations, this vision led to a perilous path of unintended consequences. Early connected worker deployments prioritized efficiency gains over human agency, reducing workers to passive monitors and stripping away their role as problem-solvers. This gave rise to The Autonomy Gap: a widening chasm between advanced digital infrastructure and the worker’s actual ability to influence outcomes.

The human impact was tangible. Confronted with stifled agency and pervasive high-tech surveillance, many frontline workers made a logical trade-off: they realized they could earn similar pay driving for Amazon or UPS - roles that, ironically, offer more independence and decision-making authority than a modern, restricted ‘smart’ factories. Industry 4.0, driven by an obsession with visibility and control, inadvertently created systems that look advanced on dashboards but remain cognitively fragile and culturally alienating on the shop floor.

History underscores a recurring pattern: every technological leap solves a technical problem but exposes a human one that demands balance. The Industrial Age mechanized production, prompting the rise of quality management. Industry 4.0 optimized cyber-physical systems and, in doing so, revealed an indispensable truth: human judgment, creativity and contextual care remain irreplaceable.

The Core Assumption that Broke the System

At the heart of Industry 4.0 lay a deceptively simple assumption: if machines are consistent and humans are variable, then machines deserve more trust. This automation-first mindset hardened into doctrine. Decision-making authority migrated to algorithms, and work was broken down into rigid, scripted tasks. Humans, once skilled craftspeople and agents of judgment and problem-solving, were progressively reduced to passive monitors of technology.

However, Industry 4.0’s technology-first approach was not wrong; it was incomplete. In perfecting precision, it slowly starved purpose. This was not a failure of will, but a failure of design. The logic felt sound: machines do not tire, hesitate or feel. In environments obsessed with efficiency, predictability masquerades as safety. But predictability is not resilience, and consistency is not intelligence.

Why Automation Felt More Reliable than Humans

Cognitive science reveals persistent bias: people tend to over-trust automated systems, even when they are flawed. Automation earns trust early through apparent competence, and once established, trust calcifies even as system performance declines. Consistency becomes a psychological anchor; human variability feels risky.

This bias is amplified by leadership priorities. Global surveys confirm that executives consistently favor automation over human development. Deloitte’s 2023 Manufacturing Industry Outlook found that 64% of manufacturing executives ranked ‘automating processes’ as their top operational priority - far above human capital initiatives (Deloitte, 2023). Similarly, the World Economic Forum reports that 85% of employers believe technology adoption is the trend most likely to transform their business, while workforce strategies are often treated as reactive (WEF, 2023).

The outcome is telling: automation ‘wins’ not because it is inherently better at adaptation, but because it is easier for executives to quantify and trust. Industry 4.0 did not merely deploy technology; it institutionalized this bias.

From Augmentation to Marginalization

As automation became the default source of ’reliability,’ the human role was steadily diminished. Workers were pushed to the perceptual edges of increasingly complex systems. Judgment was replaced by procedure, and context disappeared beneath layers of dashboards and alerts. Humans, once creators of value, were reduced to passive monitors, summoned only when automation faltered.

In the process, something essential was engineered out. A distinctly human-shaped absence emerged, an empty space where judgment, meaning and agency once lived. What filled that space was not intelligence but rules; not understanding but thresholds; not purpose but control logic.

The consequences were profound:

- Cognitive Deterioration and Atrophy of Expertise: Critical thinking and problem-solving muscles atrophied

- Eroded Situational Awareness and Loss of Context: Workers lost a holistic understanding of operations

- Decline in Synthesizing Ability and Disconnection from Weak Signals: The capacity to grow tacit knowledge and anticipate failures vanished.

Paradoxically, systems engineered for peak efficiency dismantled the very human capabilities needed to rescue them in times of crisis.

"The Man and the Dog” as a Dangerous Architecture

The ‘lights out’ factory was more than a joke; it was an architectural manifesto. Human factors experts describe this as the Human Out Of The Loop (HOOTL) paradigm. HOOTL designs create a dangerous paradox: humans remain passive for long stretches, then are expected to perform flawlessly under extreme pressure the moment automation breaks down.

AI maturity does not eliminate the need for humans; it amplifies the cost of their absence. As systems grow more intelligent, human judgment becomes more valuable, not less, because of the consequences of misinterpretation, delay or ethical error scale with system power.

Neuroscience and high-reliability organization research converge on a simple truth: situational awareness and expert judgment cannot be preserved without active engagement. Reliability is not a property of machines alone; it is cultivated, or lost, through continuous human practice in the loop.

The Real Reason Most Digital Transformations Failed

Most digital transformations failed not because of technology, but because of flawed anthropology. By optimizing machine efficiency, Industry 4.0 stripped work of meaning, agency and cognitive engagement. The workforce was present but increasingly disengaged. When novel edge cases emerged, the scenarios that AI cannot anticipate; organizations often paid the price. The people who should have been the system’s ultimate resilience layer were reduced to its weakest link.

The grand illusion of Industry 4.0 was equating automation with resilience. Resilience is a human-led capability, sustained through active engagement, contextual judgment and adaptive problem-solving. Machines excel at execution within known parameters, but only humans can care about outcomes, interpret novel meaning and creatively orchestrate responses to the unexpected.

Breaking the Illusion: The Imperative of Industry 5.0

Industry 5.0 is the necessary correction. It rejects HOOTL entirely and recognizes that in a world of increasing volatility, humans are the primary source of adaptive capacity, resilience and innovation - not a variable risk to be mitigated.

This is not a retreat from technology but a strategic reposition. The goal shifts from replacing humans to amplifying them.

Industry 5.0 is not simply re-adding people to automated systems; it is about redesigning work around what only humans can do - and what humans can do better with intelligent support. Automation delivers the cold precision of the how, while humans remain the architects of the why.

Workers become orchestrators and decision-makers embedded in purposeful work, while machines manage deterministic tasks. Where failed digital transformations treated humans as peripheral to automated cores, Industry 5.0 reverses the relationship.

The digital ecosystem becomes the support structure for a human-centric core, continuously strengthening human adaptive capacity, building enterprise-wide resilience and enabling sustained innovation.

Investing in technology without considering human agency can create brittle systems. Any Connected Worker strategy for 2026 must center on three pillars:

- Cognitive Augmentation: Deploy technology (AI copilots, AR, spatial computing) that delivers context-aware information to enhance human judgment, not replace it

- Operational Autonomy: Design workflows that provide guardrails but return authority and agency to frontline workers to solve problems within defined spheres

- Human-Centric KPIs: Measure and incentivize flow, engagement, cognitive velocity and innovation alongside efficiency and productivity.

For 2026 and beyond, the mandate is clear:

Humans are the foundation of resilience.

Machines are instruments of precision.

The future belongs to organizations that design systems where humans operate at their cognitive, creative and collaborative best. Industry 5.0 represents a strategic and philosophical shift, moving beyond the aspirational ’lights-out’ factory toward adaptive, resilient, human-centered operations. This requires a new workforce model where automation and humans work in tandem, each amplifying the strengths of the other.

By intentionally integrating technology with human judgment, organizations can continuously learn what to automate, what to humanize, and how to co-bot most effectively. Where automation once outpaced human adaptation, Industry 5.0 envisions a future in which humans and machines evolve together in a self-reinforcing loop, continuously enhancing each other’s strengths and safeguarding weaknesses.

Looking for more expert takes? Read Brent’s full collection of further insights on the connected worker here.

The Human Imperative of Industry 5.0

Industry 4.0 proved that automation alone cannot deliver resilience. As we navigate 2026, the shift from Industry 4.0 to 5.0 is being accelerated, powered by connected worker innovations such as AI copilots, spatial computing and advanced flow measurement. Yet the true power of these technologies lies not in their technical specifications, but in their ability to finally close The Autonomy Gap.

The goal is not simply more technology, but a smarter synergy that generates coequal economic and human value. The future of industrial excellence depends less on machine control and more on human clarity, connection and care (see sidebar). If Industry 4.0 optimized the machine, Industry 5.0 must optimize the mind.

Within this framework, technology becomes a catalyst for growth - not a source of displacement or fear. Automation is repurposed to amplify judgment and agency, removing the structural frustrations and digital tethers that have historically driven talent away. By increasing both the density and intensity of meaningful work, these innovations allow employees to reclaim their roles as orchestrators of the system.

The result is a HumanBright Enterprise: a workplace where people do not merely monitor machines, but engage in purposeful work they genuinely care about, driving a level of performance no ’lightsout’ factory could ever achieve. In the end, resilience belongs not to automation, but to the humans empowered to shape it.

References

Bainbridge, L. (1983). Ironies of Automation. Automatica, 19(6). (Foundational source for the "Human-Out-Of-The-Loop" paradox and cognitive fragility).

Bennis, W. (1997). Managing People is Like Herding Cats: On Leadership. Executive Excellence Publishing. (Source for the “Man and the Dog” factory architecture metaphor).

Deloitte. (2023). 2023 Manufacturing Industry Outlook. Deloitte Insights. (Cites executive prioritization of process automation over human capital).

MIT Work of the Future. (2022). The Work of the Future: Building Better Jobs in an Age of Intelligent Machines. MIT Press. (Evidence for the "Autonomy Gap" and why workers migrate to roles with higher situational agency).

MIT Sloan Management Review & BCG. (2022). Expanding AI’s Impact With Organizational Learning. (Empirical data on the necessity of human–machine mutual learning).

World Economic Forum. (2023). The Future of Jobs Report 2023. (Data on technology adoption versus workforce strategy).

StartUs Insights. (2025). Industry 5.0 Market Report 2026: Top innovations and trends. StartUs Insights. (Highlights adoption of cobots, spatial computing, and immersive AR/VR interfaces for human-centric operations).

Wang, Y. (2025, July 1). The Rise of Collaborative Robots: Technical and Commercial Insights. IDTechEx. (Documents the growth of cobots supporting human decision-making and safety in Industry 5.0).

Electronics360. (2025). 25 Trends in Robotics for 2025. GlobalSpec. (Notes collaborative robots, AI autonomy, and human–robot interaction).

Forbes (Moor Insights). (2025). ERP Shifts to Industry 5.0 to Enable Smarter, Human-Centric Operations. Forbes.com. (Shows AI copilots and systems designed to augment human judgment and creativity).

IFAC PapersOnLine. (2025). Trends on Human Factors in Industrial Human–Robot Collaboration: From Design to Implementation. (Emphasizes worker involvement and human-centered feedback loops in Industry 5.0 systems).

Financial Times. (2025). Successful AI Adoption Needs Workers in the Loop. (Highlights that AI effectiveness depends on human agency and participation).